Custom digital twin development has proven highly efficient in many domains, from healthcare to the oil & gas sector. This software solution simplifies smart manufacturing for companies and reduces the time and costs involved in industrial production, provision, and repairs.

In this article, we explore the essentials of digital twins in manufacturing, how they solve the main problems industrial companies may face, real-world examples of their implementation, and the steps to begin digital twin development.

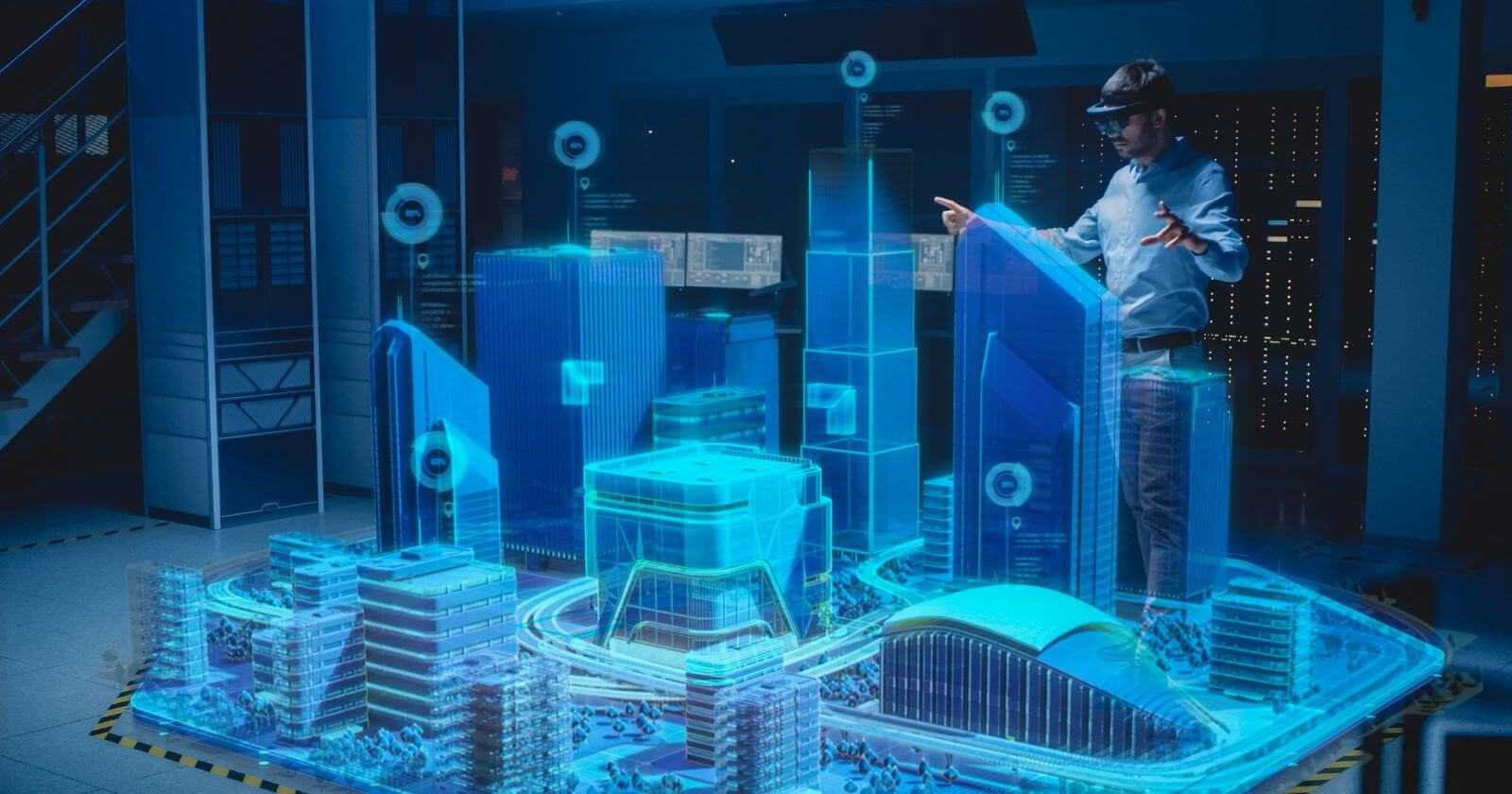

Introduction to Digital Twin in Manufacturing

The concept of virtual twin is not so new to the manufacturing enterprises. However, a few decades ago, businesses could only imagine the potential of this software solution as they had challenges like high costs for computing, storage, and bandwidth.

Technological progress and the Fourth Industrial Revolution (Industry 4.0) solved the above-mentioned obstacles. Furthermore, owing to the advanced capabilities of 3D, now virtual models represent and simulate physical objects or processes in a virtual environment more accurately.

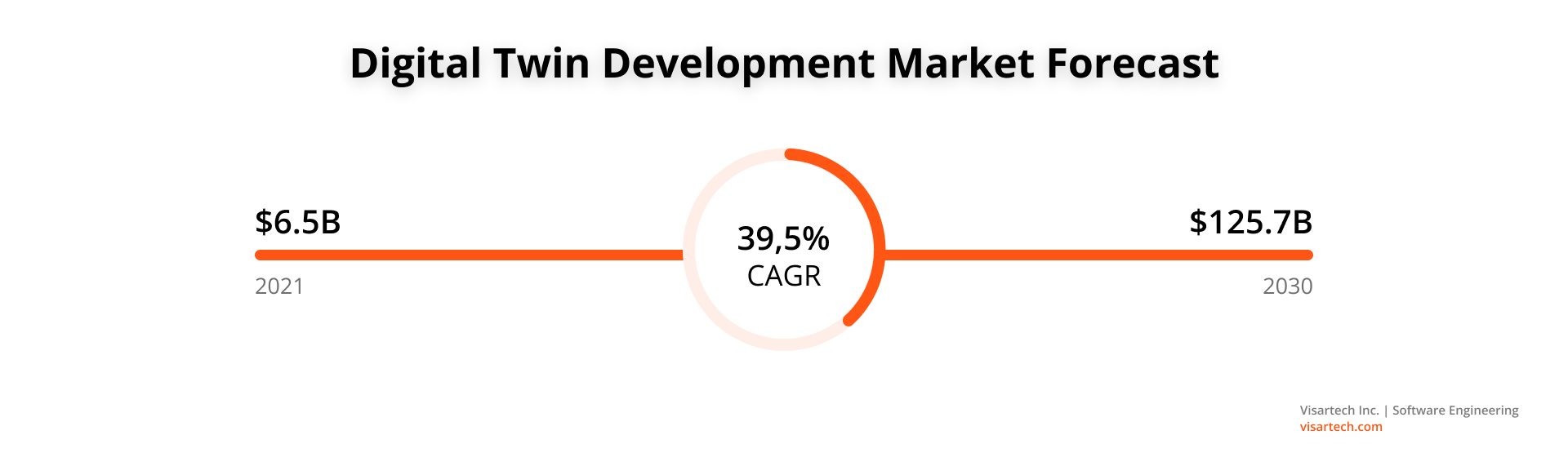

So today, digital twin development services are in demand among big players in the manufacturing domain. The Allied Market Research reported that the global virtual twin market size will reach $125.7 billion by 2030. As for the manufacturing companies, in 2020 they accounted for a share of 22% in this sector, establishing itself as the foremost segment for digital twin development.

But what is a custom digital twin in manufacturing, by definition?

The digital twin recreates physical objects, assets, and operations, allowing for timely and cost-effective optimization, process monitoring, improvement, and maintenance. This is what Industry 4.0 stands for. The digital twinning in manufacturing uses current operational data to create a synchronized copy that executives can rely on. The metrics from the object are then used to model and predict its status in the ever-changing working environment.

Read more: Digital Twin Development Benefits and Costs

Learn ways digital twin technology can update your businesses

The most revolutionary thing about the digital twin development for manufacturing is a step from analyzing the past to recreating real-time dynamics and predicting the future. For businesses, this means avoiding unnecessary expenses and making data-based decision.

The virtual twin evolves and reflects real-life changes in processes, personnel, and machinery. The digital twin system not only improves the productivity of a single production line. It also adjusts the production network of interconnected systems and responds to changing business requirements.

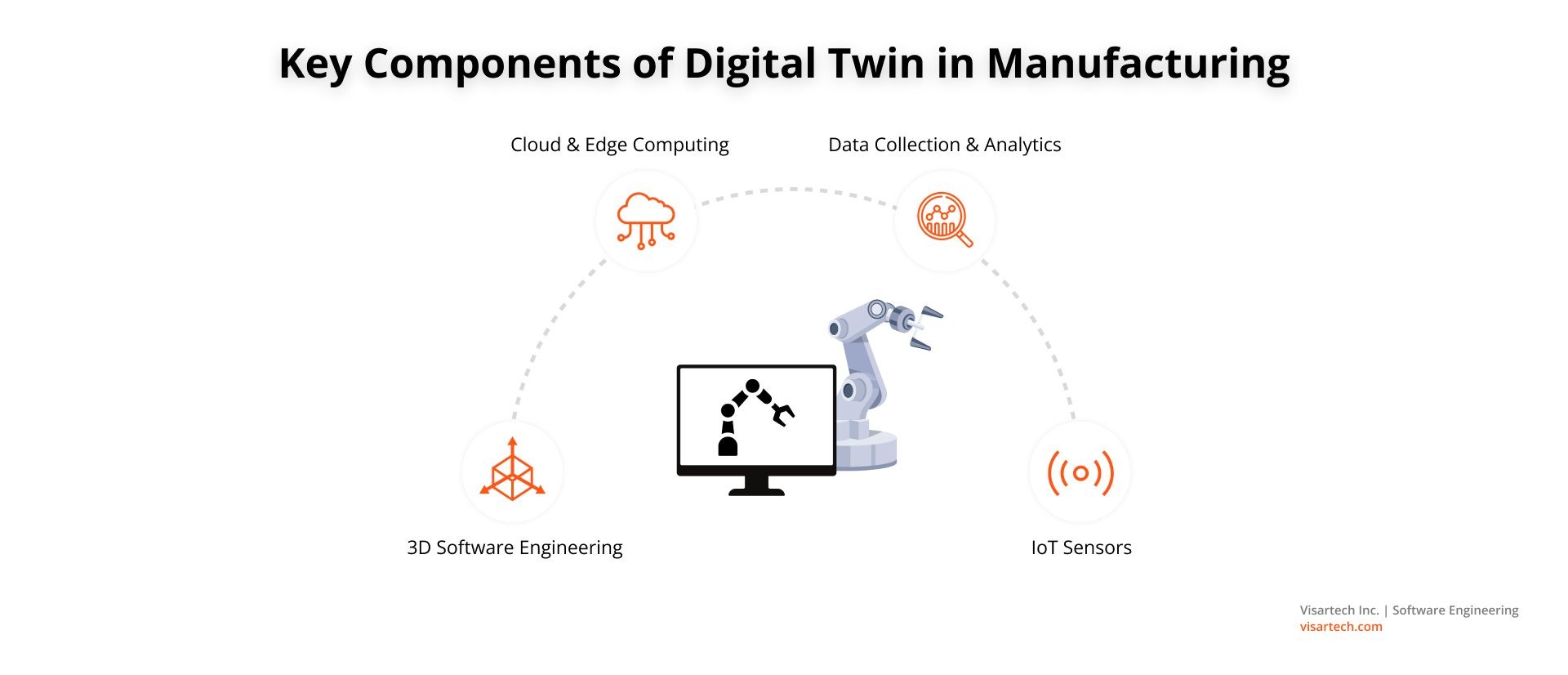

Key Components of Digital Twin in Manufacturing

To create a virtual copy, organizations leverage a combination of 3D software development, cloud computing, data analytics, and IoT. Let’s now explore these elements of custom digital twins in a little bit more detail.

3D Software Engineering

We’ve already mentioned that 3D engineering services make the digital twin look and act exactly like its physical prototype. 3D tech artists gather relevant data and specifications to understand the functional aspects of the physical object or system that is to be replicated.

Next, they take the scanned copy of an item and refine details to develop an accurate and immersive digital twin for a better user experience. The developed 3D model is then integrated into a software solution where users can interact with it.

Visartech tackles these steps by leveraging the next tech stack for 3D software development:

- Unity, PlayCanvas, Babylon.js, and three.js 3D engines;

- Steam VR, HTC Vive, Oculus VR, and Windows Mixed Reality desktop and standalone VR kits;

- Google VR for mobile VR experiences;

- Apple AR Kit, Google AR, and CoreVuforia for mobile AR.

By utilizing a wide range of 3D software engineering tools including 3D scanning and CAD modeling, we develop immersive software solutions to provide virtual training services, virtual tours, collaboration environments, and interactive apps.

Cloud & Edge Computing

Digital twin development services feed on data to generate information that manufacturers could rely on when making decisions. Cloud computing allows organizations to store and operate large volumes of data, which would be nearly impossible to accomplish on-premises. By storing digital twin data in a secure cloud environment, you can access them from any location.

The term “edge computing” means processing and analyzing data closer to its source. This results in faster response times and reducing the need for cloud-based data management.

To take full advantage of the custom digital twin development, you should depend on a cloud-based infrastructure. At Visartech, we offer advanced cloud computing services. They can include cloud infrastructure management, cloud migration, or security & compliance services. The tech stack we use is as follows:

- Infrastructure services – Amazon Web Services, Microsoft Azure, Google CloudPlatform, Docker, Kubernetes, and Firebase.

- Web backend – NodeJs, ASP.NET, Java, Django/Python.

- Frontend development – HTML/CSS, Javascript & jQuery, TypeScript, ReactVue, A-Frame.

Check out the expertise page to find out more about our software solution cases.

Data Collection & Analytics

Data collection is gathering information from sensors, gadgets, and other sources related to the physical system or object that the digital twinning represents. For example, data about temperature, pressure, movement, or any other relevant parameters.

When all the information is collected, the digital twin analyzes it using specific techniques and algorithms. It helps manufacturers better understand the behavior, performance, and possible issues of the item.

We rely on this tech stack when collecting and analyzing data: Microsoft SQL Server, MySQL, PostgreSQL, MongoDB, Redis, Azure Cosmos DB, Azure Table Storage, and Amazon DynamoDB.

Read also: Digital Twin Architecture and Implementation

Discover a comprehensive guide to creating Digital Twins

IoT Sensors

To develop an operational digital twin, it’s necessary to connect it to IoT sensors. These sensors will capture the required data and metrics on the object’s performance. The digital twin system receives the data gathered by IoT devices. Thus, the virtual model instantly captures the state of the actual production assets.

For manufacturers, IoT devices are another source of valuable information. They help analyze the performance and behavior of their factory’s assets, make informed decisions, and optimize production processes.

As you can see, entering Industry 4.0 with the help of virtual representation requires digital twin development services with specific expertise. By comprehensively approaching the building and implementation of all the four elements described, you have every chance to create the digital twin that transforms the way we do manufacturing.

Digital Twin in Manufacturing vs. Industrial Metaverse: What’s the Difference?

The industrial metaverse acts as a separate digital ecosystem that includes components of production operations and networks while digital twins are copies of physical objects or processes included in the digital manufacturing domain.

The key differences between these 3D software solutions are:

- Scope

The metaverse encompasses a broader scope compared to building a digital twin in a manufacturing business. It includes virtual representations of interconnected systems, energy management, and collaborative planning involving manufacturing processes.

- Purpose

Through simulation, digital twinning offers real-time manufacturing process improvement, data monitoring, and maintenance forecasting. The industrial metaverse facilitates seamless collaboration among stakeholders such as suppliers, manufacturers, and distributors through integrated planning and cross-domain cooperation.

- Data Collection Methods

The manufacturing digital twin focuses on simulating physical assets using sensor data, precise 3D models, and historical records as resources. Meanwhile, the industrial metaverse leverages technologies like VR/AR and digital sensors to create immersive virtual environments and collect data from both the real world and virtual interactions.

- Development Time

On average, the building of the industrial metaverse prototype will take 21.75 FTE (full-time equivalent) where one FTE is a 40-hour working week. The custom digital twin development, in turn, requires approximately 8 FTE.

Both the digital twin and industrial metaverse have unique characteristics that foster manufacturing businesses. In case you aim to create holistic collaboration within the whole production ecosystem, the metaverse will serve better. Virtual representations, on the other hand, focus on optimizing specific objects or processes and provide valuable insights for predictive maintenance and operational activities improvement.

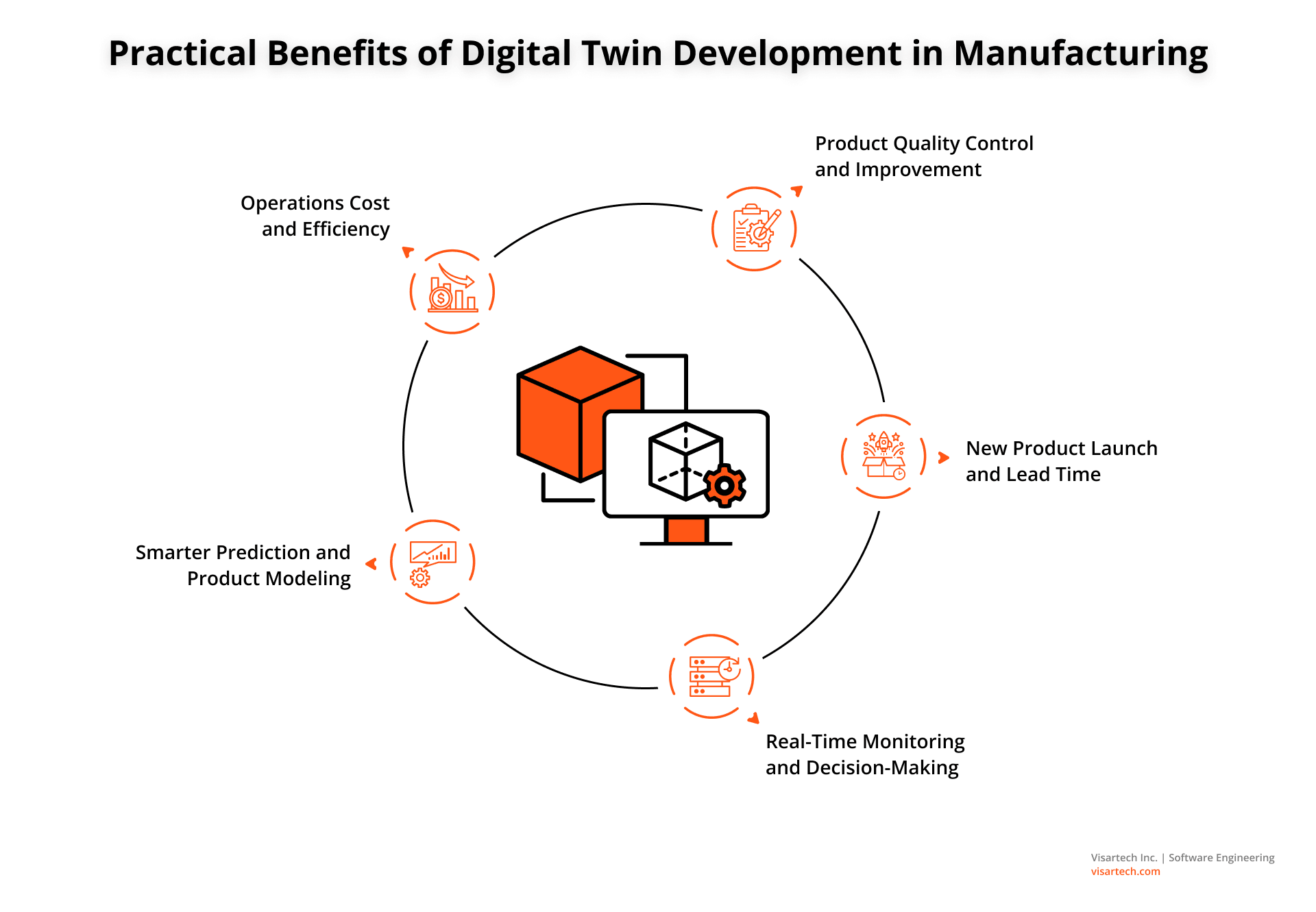

Practical Benefits of Digital Twin Development in Manufacturing

When it comes to manufacturing complex products, companies often face challenges such as accurately tracking the complete production history of each unit. So they spend too much effort to get really quality items.

Digital twins offer predictive modeling of all the product’s or system’s components based on real data. As such, the development of this software solution brings the following benefits to manufacturing enterprises:

Operations Cost and Efficiency

Testing product characteristics pre-manufacturing is probably the most obvious advantage of creating a digital twin from a cost-effectiveness standpoint. However, there are other factors contributing to the reduction of operational costs:

- Better equipment performance;

- Decreased variability of processes;

- Better engineering and design;

- Timely support and maintenance.

Product Quality Control and Improvement

A digital model shows real-time data on the precise condition of assets or systems. This enhances the user experience because managers always have access to information about problems with products from any location. Consequently, organizations improve product quality, reduce maintenance and avoid downtime.

New Product Launch and Lead Time

A digital twin process not only reduces the costs of a new product but also speeds up its launch date. The product journey from the ideation stage to customers is shorter and easier. This is because the information generated by digital twinning helps identify and eliminate obstacles before they hinder production.

Real-Time Monitoring and Decision-Making

Digital twin development also simplifies managing all the processes for manufacturing organizations. Receiving analyzed data just from 3D models saves employees’ time while increasing productivity and bringing valuable insights for informed decisions.

Smarter Prediction and Product Modeling

Imagine a digital space that is a copy of your factory. It shows all the ongoing operations within it. You can use such a plant digital twin to predict what resources (production lines, warehouse space, etc.) you will need to manufacture new products. By conducting real-time analysis within this online platform, you gain convenience in implementing necessary modifications directly at the physical factory.

The digital twins in manufacturing boost product quality, reduce maintenance and operating expenses, and accelerate innovations giving companies competitive advantages. Let’s now explore how manufacturing businesses use this custom software solution.

How Do Digital Twins Transform Enterprise Operations?

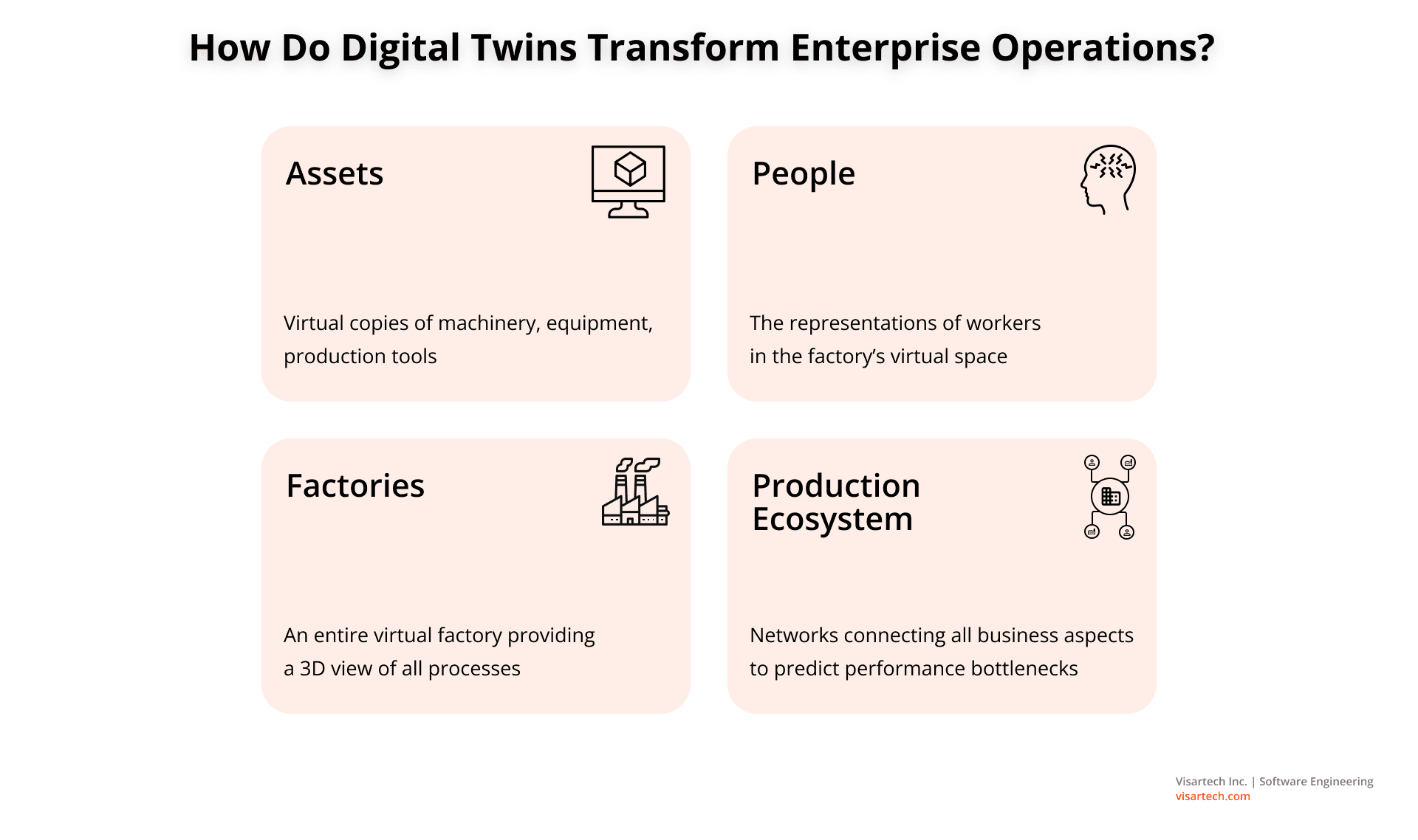

Practically speaking, there are four ways in which enterprises may leverage bespoke digital twins. We could also view these aspects as angles from which virtual copies are impacting smart manufacturing.

- Digital Twins for Assets

A digital twin simulation replicates manufacturing assets: machinery, equipment, production tools, etc. They offer data on the operating status, performance information, and environmental conditions of an object. In case a manufacturer has twins of two or more assets, the virtual representations will show how they interact with each other and with the production environment.

For instance, consider a digital twinning in the NDT (Non-Destructive Testing) industry that incorporates 3D models of critical structures or components undergoing inspection. The virtual copy tracks material integrity, corrosion levels, and anomalies with NDT techniques like ultrasonic, magnetic particle, and radiographic testing. If a defect is found, the digital twin quickly analyzes the data and identifies the root cause.

Visartech has expertise in developing the Digital Twin Solution for a Leading NDT Provider. It’s a 3D model of 3-axis scanner components for a web-based virtual twin. You can view the device by rotating it 360 degrees and explore its core functions through digital simulation.

- Digital Twins for People

Employees can also have their representations in the factory’s virtual space. Factories in dangerous settings can monitor their physical and emotional well-being with sensors to avoid accidents and exhaustion. Also, this information helps to track and improve working conditions and create a favorable environment for human-machine interactions.

Digital twin development also has practical applications for training in created simulations and testing employee skills.

Read more: Digital Twin for Corporate Learning and How to Implement Them

Discover how to advance corporate education through digital twins

- Digital Twins for Factories

A factory digital twin is a 3D model of all the interactions within your smart plant. To create such a virtual twin, you need to connect all factory operations and track data.

A digital twin for factories showcases the collaboration of various components within a company’s production sector. Operators can explore and experiment with these components to determine their optimal performance and offer ideas for process optimization.

- Digital Twins for Production Ecosystem

The custom digital twin development services enables manufacturers to create a full-scale ecosystem connecting every aspect of a business: people, processes, and factories. It’s also possible to develop a platform linking digital twin networks between companies. By doing this, we can view the interactions of the entire supply chain.

The production digital twin connected to the same system in another factory helps predict performance bottlenecks, resource needs, and environmental impact.

Assets simulation is currently the most common way of using a digital twin development in manufacturing. As you can see, though, the digital twin applications in manufacturing extend much further.

Today, most enterprises recognize the impact of the virtual twin in industrial production. Some are already reaping benefits but this path also involves risks. Below is an ultimate overview of the challenges enterprises may face when adopting the digital twin in manufacturing.

Risks & Challenges of Digital Twin Development for Manufacturers

For optimal effectiveness, it is essential to monitor, oversee, and protect manufacturing digital twins as they progress through the organizational pipeline. Activities that contribute to this may include certain challenges.

But don’t worry, all risks related to digital twin development and adoption can be mitigated and this section provides handy tips on how to do it.

Data Integration and Compatibility

The challenge at hand stems from the diverse sources of data that digital twinning has gathered. This means that the received information differs in format, structure, or communication protocols. Besides, various methods of transferring the collected data complicate the integration process itself.

To solve data integration and compatibility problem, consider the following actions:

- Standardize data formats and protocols to ensure system compatibility;

- Make investments in reliable data integration platforms and middleware;

- Rely on tech providers who can create specialized connectors and interfaces;

- Implement data management methods for their correctness, consistency, and quality.

Data Quality and Security

For manufacturers to see the real status of their production processes, systems, and assets, the data collected by 3D models must be as accurate as possible. When it comes to data security, the challenge lies in the fact that digital twins are interconnected with numerous networks. So it’s hard to monitor and ensure reliable protection for all of them.

The solutions for mitigating data quality & security risks are:

- Create procedures for data validation and verification to guarantee data integrity;

- Apply cybersecurity practices – encryption or access control to each network;

- Maintain regular data backups for recovering lost or corrupted data.

Flexibility and Scalability

Your digital twin should respond to changes inside the manufacturing business. For instance, when you expand production capacity, it becomes imperative to initiate custom digital twin development for the new production line or a facility in a different geographic location.

It’s also important to change the setup of the virtual representation with the launch of a new product or production process. This ensures that your software solution accurately mirrors the present parameters, functionalities, and requirements.

Here’s what to consider when developing manufacturing digital twin that responds to business changes:

- Keep in mind the adaptability of your virtual copy from the outset;

- Adopt open standards and modular architectures to make integration simple;

- Create precise rules for adding new machinery, procedures, or items to the digital twin;

- Update the digital solution frequently to account for changing business requirements.

Reliance on Technology Infrastructure

The optimal performance of the digital twin relies on its underlying subsystems that diligently facilitate its operation. This includes networks, servers, and data stores. Thus, any disturbances that the IT infrastructure encounters will impact the precision and accessibility of the virtual twin.

Activities to do when reducing the chance of IT Infrastructure and digital twin breakdowns are:

- Use failover and redundancy measures to lessen the impact of failures;

- Frequently monitor and upgrade IT Infrastructure for optimal performance;

- Apply recovery measures to quickly restore the virtual twin in case of interruptions.

Now that you know which risks pose digital twin development in manufacturing and ways to mitigate them, let’s take a look at how market-leading enterprises develop and integrate this software solution into their production processes.

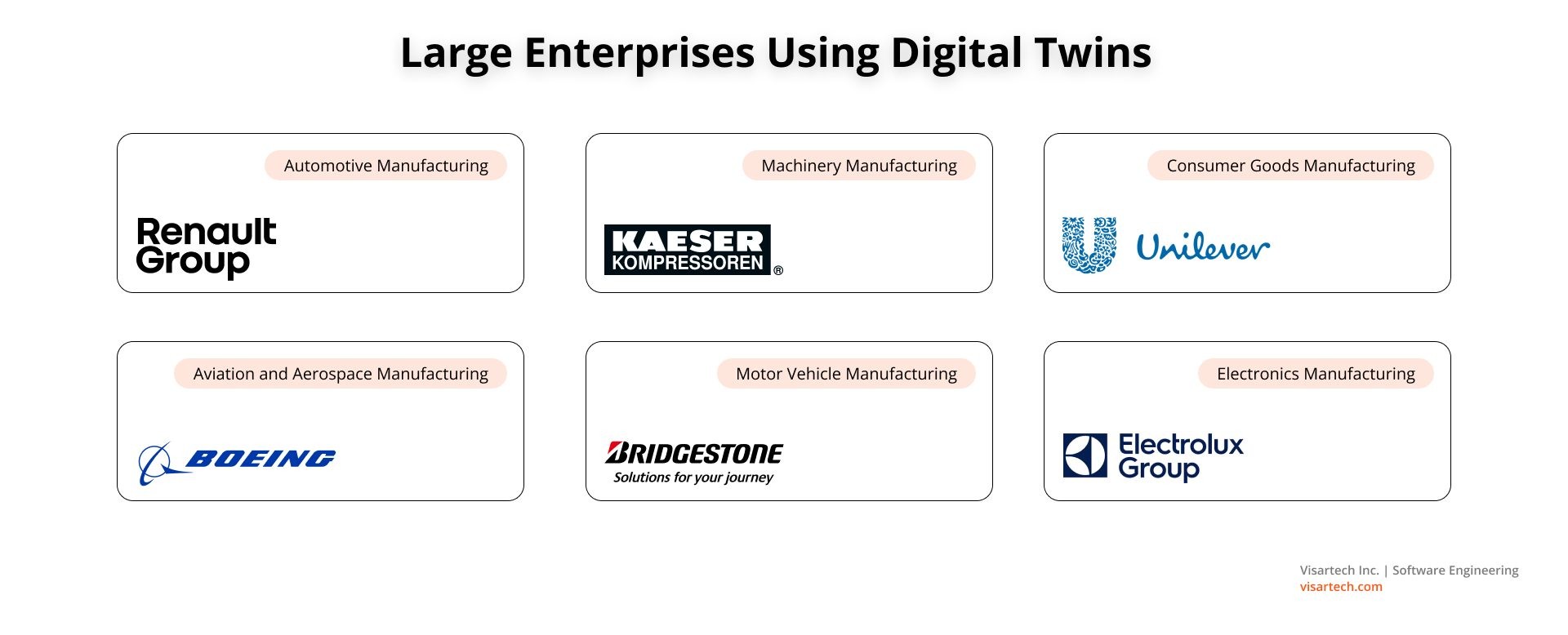

6 Enterprises that Have Developed Digital Twin

Even though digital twin development services are popular not for so long, industry giants from different domains have already embraced them. Today, the list of companies using custom digital twins to boost their manufacturing processes includes:

#1. Renault Group (Automotive Manufacturing)

The French automotive giant has developed a 3D vehicle using the digital mock-ups stored in the cloud. The product journey begins with creating the virtual vehicle design: from shape and appearance up to the smallest interior details. What’s more, engineers can place a 3D-based model of a person inside a future car. It provides a broad understanding of the interaction between humans and machines.

By building a digital product twin like this, Renault test vehicles in different scenarios more quickly and extensively than physical testing could possibly be. Each effective technical component is then combined into an “optimal” 3D model during this step. Once finished, this sample turns into the digital twin that is used to create the first physical vehicle.

Read also: Driving Forward: Automotive Technology Trends in 2023

Check the main technologies shaping the current automotive industry state

#2. Kaeser (Machinery Manufacturing)

Kaeser manufactures each product according to specific customer requests. The made equipment has different settings and additional features depending on the usage circumstances. This complicates the process of testing in production.

Digital twin development helps the company to determine the exact procedures for product assessment before its assembly. In case of non-compliance of the made equipment with the criteria, the system notifies the operator of necessary changes. Overall, a well-established system for monitoring product excellence greatly lengthens the product’s lifespan and improves customer satisfaction.

#3. Unilever PLC (Consumer Goods Manufacturing)

This manufacturing giant offers us one of the most impressive examples of using the industrial digital twin. The company initially began with creating customized digital twins of its eight factories spread across various regions around the world.

Unilever’s virtual twins gather information from many sources, analyze it, and display production-line problems. Employees determine ways to make the manufacturing operations better based on this data. The outcomes of digital twin development in manufacturing are impressive: the company achieved a 90% reduction in error rates.

#4. Boeing (Aviation and Aerospace Manufacturing)

Boeing has developed a custom digital twin to streamline the design of upcoming aircraft. Virtual representation simulates the plane’s flight and forecasts component productivity throughout the aircraft’s life. This way, engineers can foresee when parts will fail.

Another Boeing’s digital twin use case is determining the loading of aircraft freight. While manual calculations show incorrect data and planes fly with less cargo, 3D models provide precise and secure load identification, resulting in enhanced outcomes for the company.

#5. Bridgestone (Motor Vehicle Manufacturing)

Another example of a custom digital twin development is a Bridgestone case study. The company developed a virtual twin to estimate how various conditions including driving styles will impact their products. This helps vehicle fleets pick the optimal tire options for their purposes. Thus, the manufacturer may extend product lifespans and safeguard the wheels against breakage.

The company also uses virtual models to test and design its products. The assessment in a virtual environment accelerated production by almost 50%. These results drive Bridgestone to increase the digital twin use cases to link its entire value chain – drivers, fleet managers, retailers, distributors, and manufacturers.

#6. Electrolux (Electronics Manufacturing)

The company built a digital simulation of both the factory and the material flow in order to boost production capacity and efficiency. Due to the implementation of the pilot project, Electrolux managed to bring the products and manufacturing lines to the desired standard. Further, the company plans to launch a series of employee training to familiarize all its workers with the digital twins.

Bernd Ebert, Electrolux’s director of global manufacturing engineering, put it this way:

“The 3D technology helps with the verification of assembly concepts as well as with the selection of suppliers for automation solutions and provides insights that I didn’t have before.”

The digital twin examples above have shown you an answer to the question of ‘What is digital twin in manufacturing?’ and demonstrated its real value. They also can give inspiration on how to use this 3D software solution to boost the efficiency of your facility.

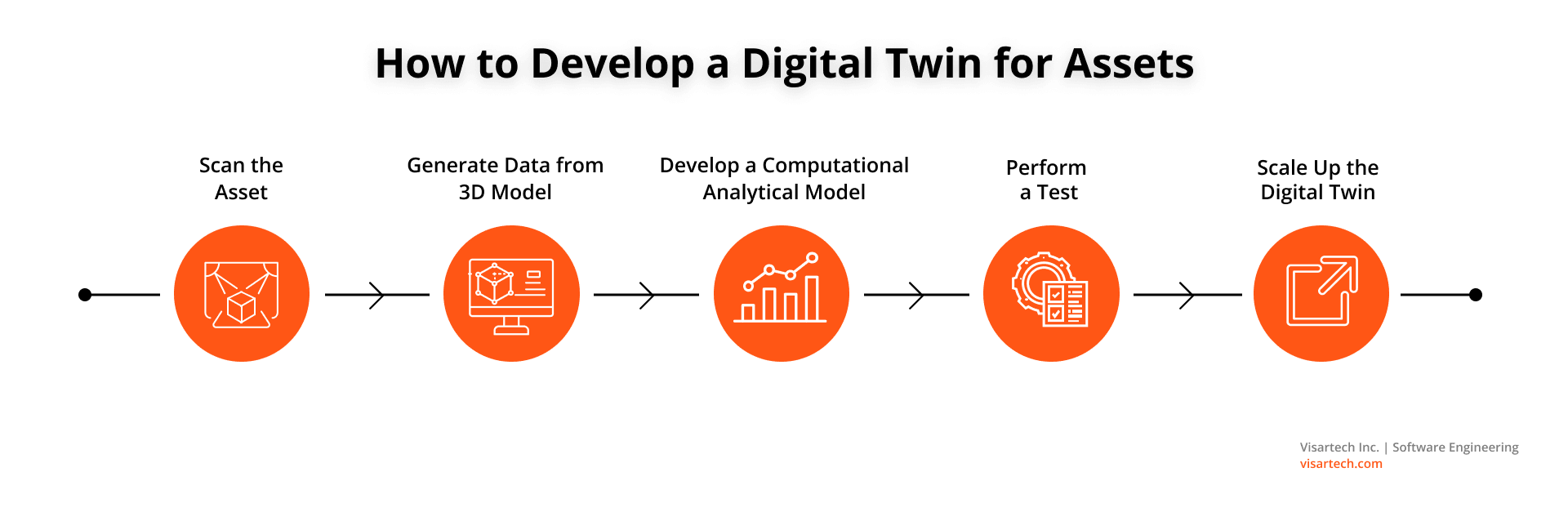

How to Start Custom Digital Twin Development?

Developing a mindful plan for custom digital twin development allows for consideration of all details in the software solution. This ensures seamless integration within manufacturing processes and minimizes business risks. For example, to develop a digital twin for assets, you need to go through the next five steps:

Step #1. Scan the Asset

Bespoke digital twin development begins with scanning assets to receive real-time data from physical items. The main methods to do it are 3D laser scanning, photogrammetry, sensor data collection, and incorporating existing CAD models and documentation.

Step #2. Generate Data from 3D Model

This step entails processing the gathered data and converting it into a format that the virtual twin can use. It is crucial to establish a reliable communication infrastructure between the physical asset and the digital twin to ensure seamless data movement. This may involve setting up data gateways, protocols, and APIs for real-time data transfer and synchronization.

Step #3. Develop a Computational Analytical Model

To produce a virtual representation that precisely depicts the system, the data must then be processed and examined. To do this, digital twin development companies leverage specific tech stack to develop a 3D model that exactly repeats the physical object and displays the analyzed data. For example, 3D representation of a workstation, whole equipment, or its parts.

Step #4. Perform a Test

Thorough testing and validation during development is a must-do to ensure that a digital twin delivers accurate data and results. This step guarantees the maximum value of virtual twin implementation, as it helps to hone the plan and avoid generating sunk costs.

Step #5. Scale Up the Digital Twin

The previous stages have shown what to improve or add to the digital twin, so it’s time to expand it and accelerate ROI. Create an operational model that will allow successful ideas to be scaled up quickly.

This is what the typical roadmap for developing a digital twin of assets looks like. Follow these steps, tailor the virtual representation to align with your business settings, and consistently strive to enhance the software solution – you’ll see a corresponding upgrade in your organization.

Final Thoughts

Digital twins in manufacturing look promising from a business standpoint. Enterprises are driven to develop this software solution for their products, assets, production lines, or factories because of its benefits. Among them are high product quality, reduced environmental footprint, lower operating expenses, and overall operations efficiency.

Many companies across industries need a helping hand in building the necessary infrastructure, accurate 3D representation, and setting up the environment for successful digital twin implementation. At Visartech, we have experience in building simulations and visual representations, and expertise in technologies necessary for custom digital development in manufacturing.